<<<1/14/2003 1/15/2003 4/7/2003 >>>

*Disclaimer: I will not be responsible for any damage you do by following this procedure*

I am going to gently clean up the ports on the cylinder head before I put it on the engine. The 5MGE cylinder head is very performance oriented to begin with so there is not a whole lot of work to do here. However there are some casting ridges near the valve seats which can cause turbulence and restrict the flow of air. There are also some humps and bumps that can be smoothed out even more. The good news is this is basically free horsepower. All you need is some time and the right tools. Just think of how much you have spent on bolt on parts only to gain 5 or 10 horsepower and it will make this a very appealing mod.

Many beginners incorrectly hog out the openings on the side of the head a great deal when in reality most of the gain is in the valve seat area. There is a-lot going on in that area with the valve guide and the valve stem protruding into the port opening. The idea is to create the straightest smoothest flow in this area with no turbulence. In fact I am not enlarging the ports at all, I am only polishing them, as they appear to be plenty large. You will be using your finger a great deal during this process to feel the ports and find where the restrictions are. Your finger will be much more sensitive to the surface of the port wall than your eyes can be. Standard abrasives has posted a wonderful article on their website about how to port cylinder heads. They also sell a kit that is specifically designed for porting. It includes all the bits you will need from start to finish for a 1/4 inch die grinder. http://www.sa-motorsports.com/diyport.htm

The tools I am using for this project are an electric 1/4 inch die grinder and assorted die grinding bits. The bits I bought are very cheap but they work ok on aluminum, also they probably remove the material a little slower which will help me avoid doing huge damage if I make a mistake. An air powered die grinder would be preferable for this task as it allows you to control the speed, the optimum speed is around 15000 rpm. I am also using a Dremel tool with the drum sander attachment.

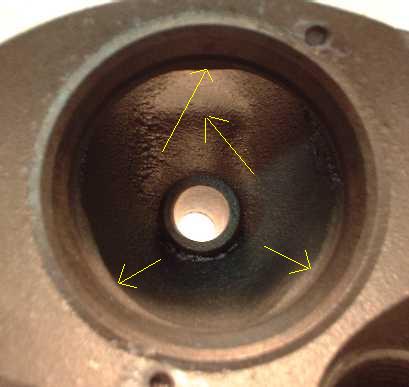

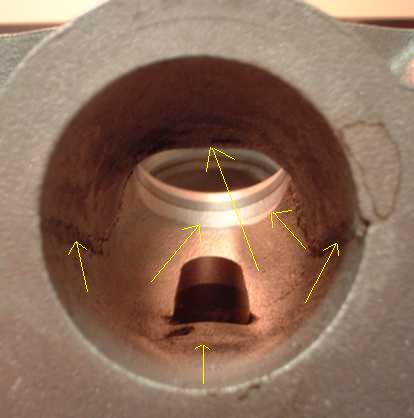

Below are pictures of the stock exhaust ports with arrows showing the areas that need your attention.

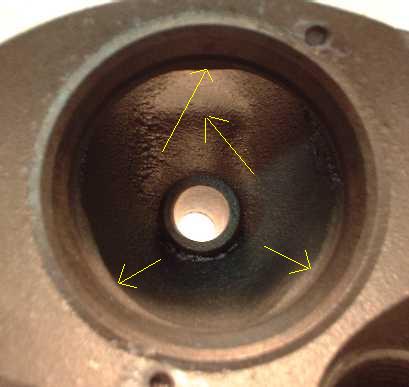

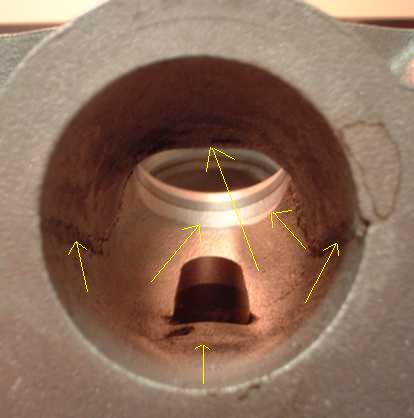

Here are some pictures of the exhaust port afterwards.

Here is a view that shows the change in the hump on the side of the port facing the cylinder head. On the left is stock on the right is ported, see the difference?

Here is the before and after series again side by side for better comparison.

Created by Wesley Hetrick 1/27/2003